Dockstr partners with SEAMOR to deliver modular ROV platforms

This collaboration expands our subsea portfolio with SEAMOR’s field-upgradeable ROV systems designed for operational flexibility, long-term serviceability, and seamless integration across inspection and intervention tasks..

Engineering Flexibility Below the Surface

SEAMOR Marine's approach to Remotely Operated Vehicle (ROV) design is centered on hypermodularity, enabling rapid customization and field upgrades without necessitating returns to the factory. By integrating modular interfaces early in the design process, SEAMOR ensures that base-model ROVs can be mass-produced and later tailored with standardized procedures, simplifying both manufacturing and sales processes .

This modular architecture allows customers to modify their systems in the field, adding or replacing components such as cameras, lights, and manipulators as needed. Standardized interfaces and practices not only streamline the manufacturing process but also ensure that new products retain a familiarity in structure and operation. This consistency simplifies engineering documentation and ensures that production and service operations remain efficient, as new designs do not catch production staff off guard .

SEAMOR's commitment to modularity and standardization empowers customers to adapt their ROVs to evolving mission requirements, enhancing versatility and cost-effectiveness across various underwater applications.

-

Design approach that allows components such as thrusters, cameras, and sensors to be added or replaced easily, enabling quick customization and system upgrades in the field.

-

Use of common interfaces and procedures across product lines to streamline manufacturing, reduce complexity, and maintain consistency in design and documentation.

-

Capability for customers to upgrade or modify their ROVs on-site without returning equipment to the factory, reducing downtime and increasing operational flexibility.

-

Base-model ROVs can be mass-produced and tailored with mission-specific modules (“decorated”), offering a balance of efficiency in production and adaptability for diverse applications.

Engineering Agility Below the Surface

This partnership strengthens our offering with SEAMOR’s modular ROV platforms enabling rapid configuration, reliable performance, and long-term serviceability in complex subsea environments.

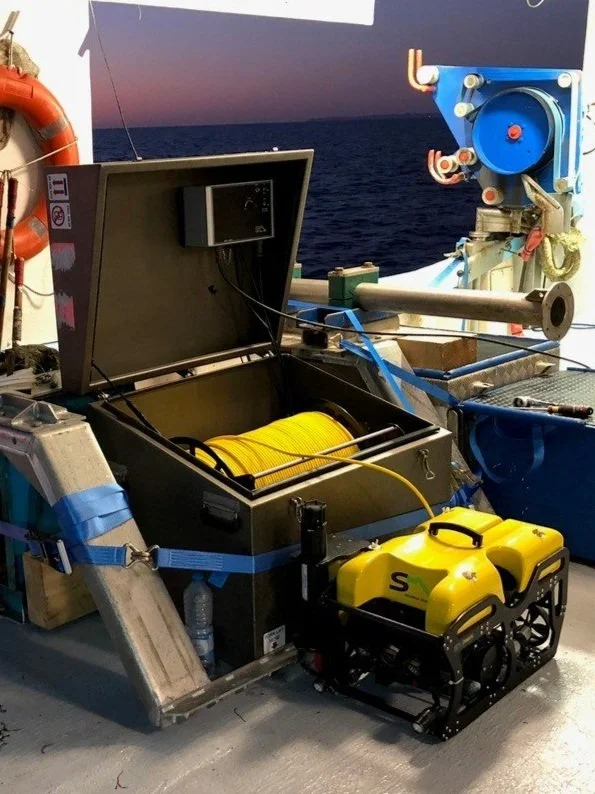

Seamor ROVs

-

Mako

The SEAMOR Mako ROV delivers advanced subsea performance in a robust 72 kg platform rated to 300 meters (upgradeable to 600), combining power, payload, and precision for professional operations.

Engineered for Stability and Visibility

With eight thrusters and a 2-knot top speed, the Mako offers precise maneuverability in harsh conditions. A broadcast-grade zoom camera, ±90° tilt, and dual LED lights ensure excellent visibility.Payload-Ready and Fully Equipped

The Mako supports up to 22.5 kg of tools including sonar, manipulators, USBL, and low-light cameras. It features a 625-meter tether, full sensor suite, and a rugged 15-inch LCD control system for reliable deployment. -

Chinook

The SEAMOR Chinook ROV combines power, precision, and portability in a 33 kg system rated to 300 meters (upgradeable to 600), offering professional-grade performance for demanding underwater tasks.

Engineered for Visibility and Control

Equipped with a broadcast-quality zoom camera, ±90° tilt, and 3,000 lumens of LED lighting, the Chinook ensures excellent visibility. Its modular thruster setup supports agile maneuvering and a 2-knot top speed.Flexible and Field-Ready

Optional tools include sonar, manipulators, USBL, and laser scalers. With 625-meter fiber optic tether capacity, integrated sensors, and a rugged 15-inch LCD control case, the Chinook delivers reliable field performance. -

Steelhead

The SEAMOR Steelhead ROV is a lightweight, 21 kg system rated to 300 meters, offering professional-grade performance for operations in shallow or restricted areas.

Agile and Visually Capable

With four thrusters and a top speed of 1.75 knots, the Steelhead delivers precise control. Its integrated zoom camera, ±90° tilt, and dual LED lights ensure clear visuals, with options for laser scaling and low-light support.Durable and Deployment-Ready

The Steelhead supports up to 335 meters of Kevlar-reinforced tether and includes full sensor integration. A rugged Pelican-case control system with a 15-inch monitor and DVR ensures dependable field operation.

Our expertise in remote intervention technology and offshore operations spanning over four decades, allows Dockstr to match our customer requirements to those products within the Ocean Robotics offerings.

Riley Marsh

Tel: +46 73 368 27 28

riley@dockstr.com